LETTUCE SPRING design process

a new take on home hydroponics

understanding the context

My goal with this project was to create something that would enable more people to grow their own food. When people supplement their diet with things they grow themselves, not only are they adding value to their life through the health benefits of eating fresh vegetables, but they also gain independence by becoming more self sufficient.

In short, hydroponics is an alternative method to soil gardening. Instead of nutrient rich soil, plants are grown in an inert grow medium, and fed with a nutrient water solution. The advantage of hydroponics is that it can grow crops faster with less work, produce larger yields in less space, and wastes significantly less water. Also, most people live in a climate where you can only grow crops outdoors for part of the year. Compared to soil gardening, hydroponics is more conducive to growing plants indoors, due to it being a cleaner, process.

There are many home hydroponic systems on the market, but none have made a significant impact. The majority of them are ugly / plastic / PVC tube type systems, which are unintuitive to use and require a lot of maintenance. They are advertised as being able to grow anything from herbs to greens to peppers or tomatoes, but to achieve those results requires a lot of know how and time.

Looking back at my first attempt at designing a home hydroponic system, you can tell I was still being influenced by the values of existing products. Although it broke away from some interaction and form paradigms, the focus of the system was still to grow as much produce as possible. This system was meant to grow herbs, lettuce and other small veggies for multiple people; just like every other system on the market.

In order to grow a high volume of plants, the system needs to be fairly large. This causes issues for multiple reasons. In addition to it being expensive and difficult to manufacture, it excludes many potential home gardeners who just don't have enough space, and due to the quantity of materials needed to keep it running, the scale may be too much of a burden to the novice gardener. I found that many of the problems which were made clear by my first design are common to most commercial home hydroponic systems.

Another obstacle in the way of hydroponics becoming mainstream, is that it's an unfamiliar concept to many people, and the majority of those who have heard of it have a skewed perception. The most common association that people have with hydroponics is that it is used to grow marijuana. When telling people about this project, more often than not I have been confronted with an initial skepticism, because when I say "it's home hydroponic system" they hear "pot growing machine". Part of my goal with this project is to make an attempt at shifting the connotation of 'hydroponics' closer to what it is in reality: a useful method of growing useful plants, not just the dank ones. This system ought to educate people about the usefulness of hydroponics, as well as helping them realize the value in cultivating their own food.

The design flaws of existing products, coupled with a general feelings of skepticism will not lead to a proliferation of home gardeners. Both of these issues come from a common source; they are both the result of ambiguity. In order for hydroponic systems to become a common household artifact, it needs to be simple in function, and clear in its message.

defining THE problem

To overcome skepticism due to illicit association, the purpose needs to be explicit. The design ought to only afford the cultivation of a specific set of plants.

To foster confidence in peoples ability to grow their own food, it needs to be intuitive. The interactions ought to be clear and dynamic.

For people to want it in their home, it needs to be beautiful. The object ought to be desired independent of its usefulness.

For it to have staying power, it must display an obvious advantage to buying produce from the store. The system should to save them money, as well as of contribute to their well being.

With these principles in mind, I framed my problem.

Create a hydroponic system designed to grow one type of plant, with enough yields to support one person.

I decided the system should grow lettuce, because it is one of simplest plants to grow, and is ubiquitously consumed.

EXPLORATION

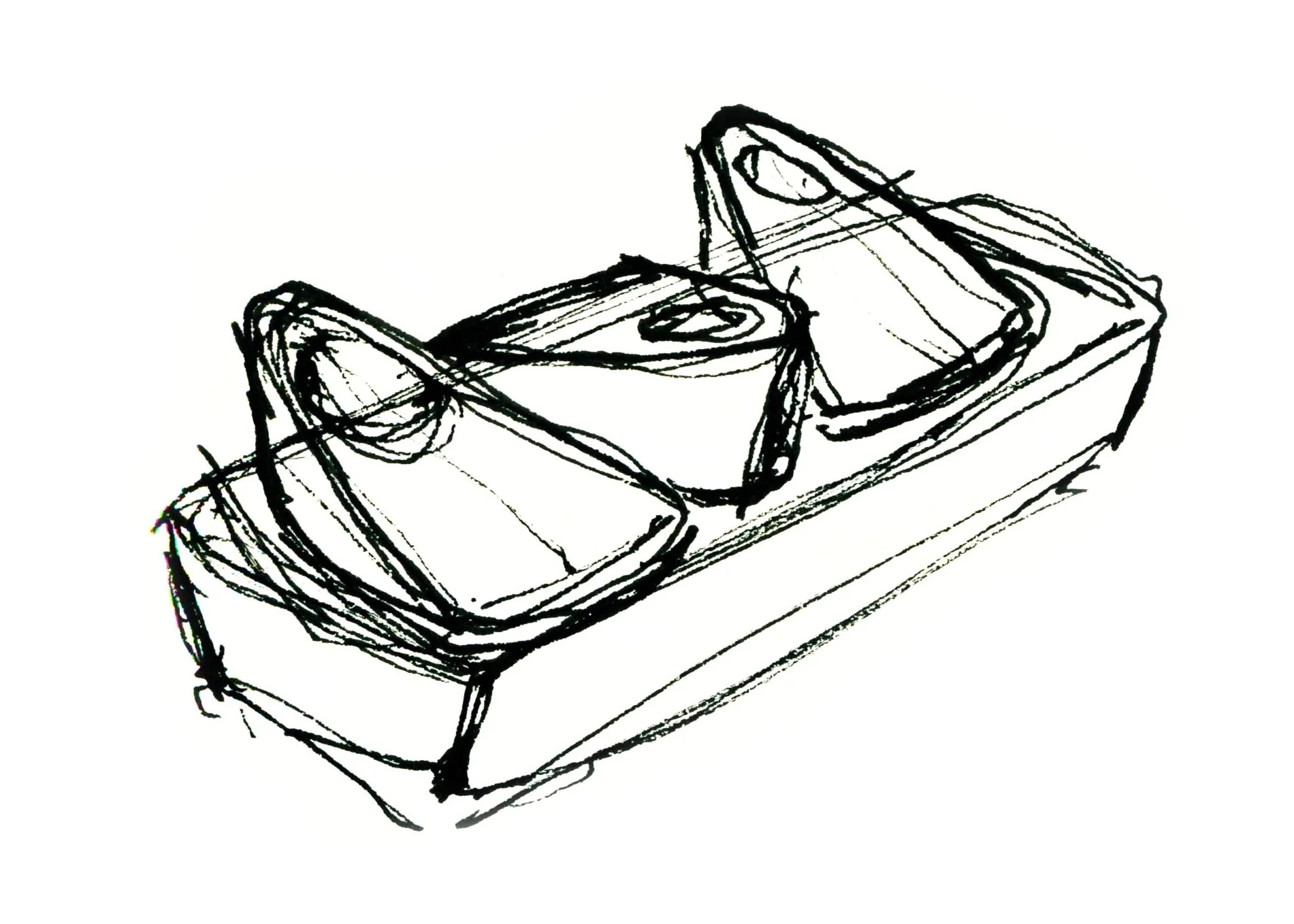

The new problem space gave rise to a variety of potential directions.

mini window garden

Essentially, these are all scaled down versions of my original design.

They hold five plants at various stages of growth. When one plant is harvested, the rest shift down the queue and a new seedling is added.

I explored staggering the plants proportional to their size.

I applied the same pattern of interaction to different forms.

In hopes of discovering novel elements, I explored unique ways of positioning the plants irrespective of the previous ideas.

mock up

In order to get a sense of what the mini window garden concept would be like in 3 dimensions, I rigged up a basic prototype.

I found this design to still be too large. Five plants felt like too many, and the interactions seemed a bit clunky. When moving plants down the queue it would be easy to damage the root systems.

This mock up made me understand the space limits of its environment. If it is to fit on a windowsill, it needs to be narrow. This out ruled the curvier concepts and the vertical systems, for they could be easily being knocked over.

soup can for scale

REACTION

The mock up made me reconsider my whole approach, so I came at the problem from a new angle.

With seedlings added on one side and full plants being taken out on the other, the previous concepts were very linear in function. Also, when starting the system, it would be mostly empty and take over a month to fill completely. This pattern of use felt too rigid, so I decided to make it more adaptable. Rather than designing a system to grow full heads of lettuce, I explored systems intended to grow lettuce that would be harvested as baby leaves, then allowed to grow back. This method allows you to have a continuous flow of lettuce with fewer plants, since you can get multiple harvests from the same plant.

single plant systems

A group of independent systems, each holding one plant. The plant lives out its entire lifecycle in one place.

Unlike previous ideas, this design is completely adaptable. They can be rearranged in different ways to suite the users need. However, since each system would need its own pump, this solution isn't energy efficient.

new direction

cell systems

I realized that elements of the mini window garden and the single plant system could be combined to create a more functional system with greater potential.

Advantages and Benefits

Each plant would have its own cell, in which it will live its entire life. This keeps the root system protected and simplifies plant maintenance because no transplanting is needed.

Cells will allow plants to be easily removed from and returned to the system. You have quick access when cooking; and can be placed on the dinner table to serve.

The cell can act as safeguard against power outages. Since it can retain a minimum amount of water, your plants are less likely to dry out and die.

A hydroponic system designed around cells affords itself to being scaled up in later versions. Once people get acquainted with a small system, they can upgrade to a larger one.

developing the cell system

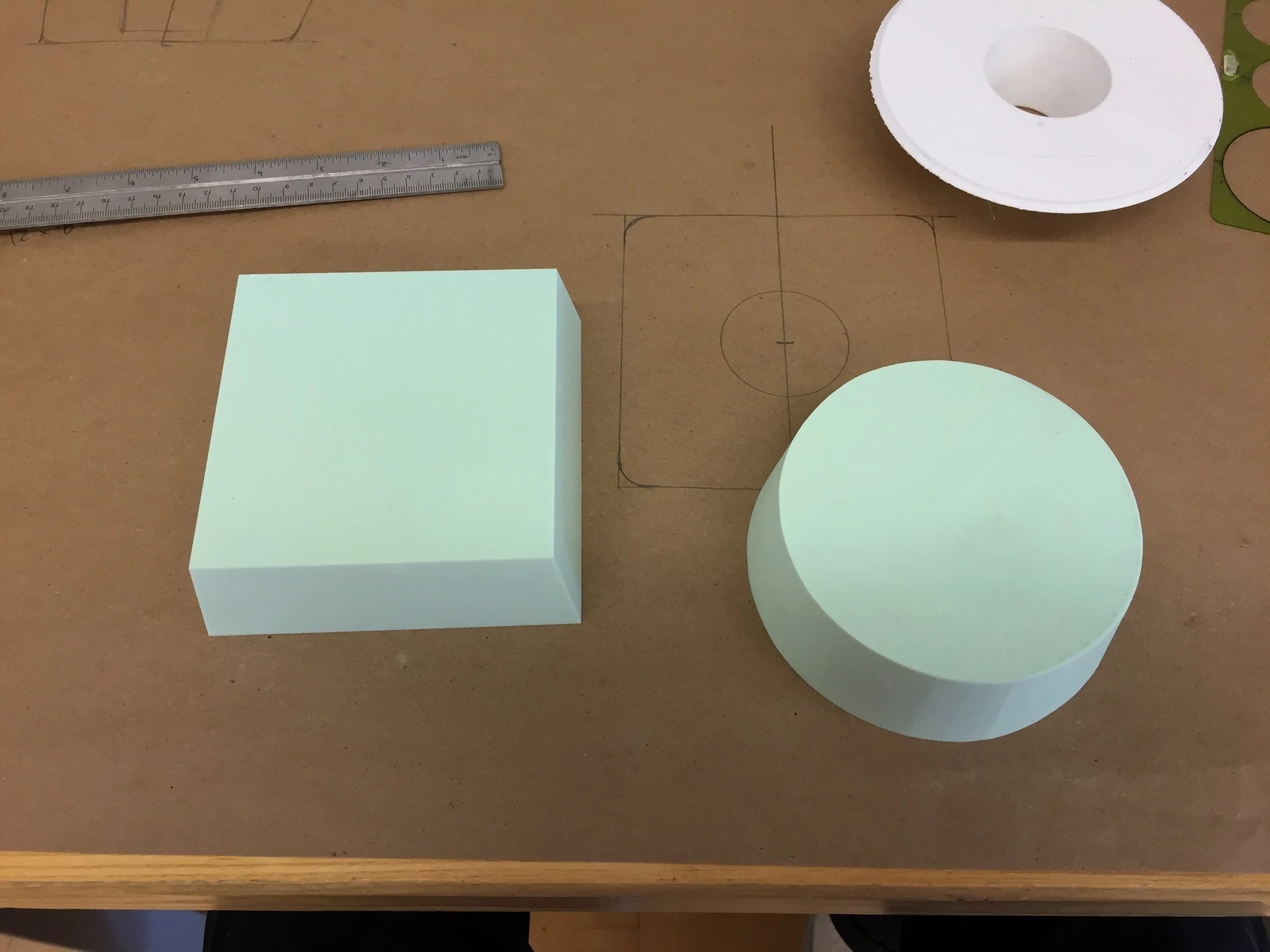

From here on, the form of the cells, and the system as a whole were explored in parallel. Discoveries made in each, influenced the other. To make models and prototypes, I use a combination of cardboard, foam, vacuum forming, and 3D printing. All computer models were made in Fusion 360.

TEST CELLS

Full sized lettuce need to be spaces 6 inches apart, so these are six inches wide.

Six inches is too large. It didn't relate well to the hand, and was more space than the plants would need.

standard cell

4 1/2" x 4 1/2" x 2"

Balance between being large enough for the plant, but small enough to hold comfortably.

cell exploration

reservoir exploration

Using the standard cell, I compared a short and wide reservoir with one that was tall and narrow.

I opted for the tall and narrow form, because it would fit better on a windowsill / kitchen counter.

integrating the light

I knew that the system had to have grow lights, but I wasn't sure if they should be there all the time. I explored different placements, and ways to hide the lights away.

Multiple systems could be linked together to be powered through one outlet.

solution

After trying a number of forms and orientations, the one that made the most sense was a rotating, light-handle that runs along the center of the major axis. This affords a light that can easily be adjusted, and provides a handle to pick up the system. In order to safely supply electricity and connect multiple systems, I added a pedestal for it to sit in.

functionally scaled down model

I modeled a reduced version to get a better understanding of how the internal elements fit together.

improving the cell

The net cup is attached to the underside of the cell top. This will keep light from penetrating into the cell and prevent excess water from evaporation out.

I wasn't happy with how deep the bottom of the cell had to be, so I domed the cell top, raising the net cup, allowing the bottom to be shallow.

I decided to go with a circular form rather than a square one for a few reasons.

In order to imbue the system with greater meaning, I wanted the system to reflect the loftier qualities of a plants life cycle. On a symbolic level, we associate circles with wholeness, fertility, continuity, renewal and health. However, the purity of a circles formlessness gives it an inherent ambiguity, for circles don't communicate a sense of direction, or afford any obvious interaction. In order to clarify how the cell relates to itself, the system and the user, I added a third dimension to the cells form. The resulting cell not only had aesthetic and interactive improvements, but also led me to discover a more elegant way of organizing the water distribution and flow.

Insights

As the function of the system became concrete in the above model, I couldn't escape the feeling that it wasn't quite right. It wasn't as elegant as it could be. There were too many points of failure where water and electricity were distributed. I realized the need to reconsider the way in which the components were organized.

Throughout this project, I had assumed that the pump should be kept in the reservoir, since that is where the water is. Realizing that I hadn't critically evaluated the best placement of the pump, I focused on new ways to integrate it.

I realized that if the pump was placed in an upper, removable portion of the system, it would eliminate several points of failure and create a compartmentalized subsystem, with the pump, water distribution, and light grouped together. Every component that relies on external energy or material is tightly integrated and everything going in or out can do so via a simple exchange. Water would be drawn up through the same opening that would allow it to return to the source, and the pump and light could join in a closed circuit, above the water line.

final mock ups

Since the pump now draws water up to the cells, a portion of the pod needed to extend down to the bottom of the reservoir. I found that this feature could be used to align the pod with the source, giving it a satisfying fit. To refill the reservoir with water, the pod is lifted up by the light handle.

the chosen form

I chose to move forward with the first option. Since the light handle is connected on both sides, it can be made to rotate while still being sturdy.

I wanted the system to communicate balance and be reflective of its function.

prototype one

refinement